Agriculture

On the sunbaked coastal plains of Almería, a sea of greenhouses stretches beyond the horizon—40,000 hectares of translucent structures, the largest concentration on Earth. Beneath them, life flourishes. Nearly half of Europe’s produce is born here, nurtured by a system that has reshaped not only what we eat but also the climate, water cycles, and local ecology. To minimize this impact, Montemero works together with farmers to develop more efficient and sustainable farming technology- like evaporation control devices, recycled plastic and mycelium seed trays and other biodegradable supplies. These technologies are tested on site in the Agriculture Lab alongside an agroecology agriculture approach, continue to find out more about our innovations.

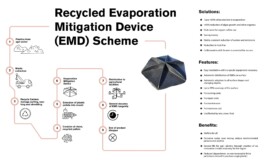

Evaporation Mitigation Device

Agriculture, Plastic, Desert

Spain

In southern Spain agriculture uses consume over 80% of available fresh water. Whats left is vulnerable to a 15% loss due to evaporation in the semi-arid region. The effects of climate change bring reality to water scarcity and the authority it plays over the region's prosperity for the future. Evaporation Mitigation Devices were designed to preserve this valuable resource, water. The floating, hexagonal pieces form a barrier against the sun and take the shape of any water reservoir.

01

In an effort to introduce circularity to the region while limiting environmental waste, we proposed an agriculture waste management scheme, enabling farmers to repurpose their spent agiplastic into new products- like EMDs. The resource saving devices are made 100% of reclaimed agripolymers.

02

A series of EMDs were formed and tested at our lab. We can report that they have shown an evaporation savings of 90% during the peak months of July, August and September. More notably, reducing algae growths by an average of 95% and therefore eliminate the need of toxic chemicals , often illegally dumped into reservoirs to prevent algae growth. These findings are the first of their kind and emphasise a REAL NEED for more research in this field for the region.

03

We have developed relations with a local agriplastic recycling facility, Green World Compounding, who is responsible for transforming large quantities of waste to a leach free composite.

04

The clean agripolymer composite can be used to produce the floating devices, a successful first for our partners Hexacover. With a lifespan of 20+ years, this technology can be applied and easily forgotten while its benefits are collected by the farmer and the environment for years to come.

"The EMDs represent more than technology—they embody a regenerative, circular future. Where waste becomes resource, and water is preserved for generations to come. A new way forward, where technology and nature work in harmony."

Germination Cells

Agriculture, Plastic, Fungi

Spain

These are the polystyrene trays that propagate young sprouts before planting. The trays are ubiquitous in agriculture and unfortunately, the environment, as strong winds and rain often carry them away. Polystyrene plastic is very difficult to recycle and once heavily soiled will likely reach its grave. We have developed several seed tray concepts to help resolve this concern.

In an effort to introduce circularity to the region, we proposed an agriculture waste management scheme, enabling farmers to recycle their spent agiplastic into new products- like seedtrays. The resource saving devices are made 100% of recycled agriplastic.

In a region where much immigrant exploitation takes place, the opportunity arose to provide young migrant workers a chance to surpass their current outlook in safe conditions with a liveable wage. With their help , 2 seed tray prototypes were developed from differing agriwaste- irrigation tubes and greenhouse coverings [white PP] and crates, twine and bulk bags [black LDPE].

To explore another area of circularity a 3rd seed tray prototype was developed using another common, but this time biodegradable, material- the tomato plant. The plant waste from tomato production was used as feedstock, mixed with mushroom mycelium and processed into an inactive form, establishing the first fully organic and compostable seed tray.

The recycled plastic and biodegradable seed trays solve several issues facing the region- give value to recycled plastic, provide examples of circularity, a solution to waste, prevent creation of excess waste, less environmental harm and many more.

PV Greenhouse

Agriculture, Desert

2018

Almeria enjoys over 300 days of sun a year making it the best place to harness the suns energy in photovoltaic solar panels. In fact the rays are so strong we’ve seen many hardy plants wither away beneath the endless days of sun, and this is where the opportunity arose. The solar panels are mounted to the roof of our greenhouse creating shade for distressed plants and purpose for the deadspace below the PVs.

The shade creates a pleasant microclimate that can be used for growing more seasonally exotic plants and produce. It also shields sprouts from aggressive pests.

Given that Almeria is known as the ‘plastic sea’ from outer space (the clusters of white greenhouses), it is clear that there is no short coming in having places to install the technology. With solar integration, these structures become more than food factories—they become energy farms, harnessing the sun twice over. By embracing rooftops as power stations, we protect the wild landscapes they would otherwise rest on

The next phase brings SolarHoop, an advanced PV film designed for greenhouses—flexible, lightweight, and seamlessly woven into the structure itself. Unlike rigid panels, SolarHoop breathes with the greenhouse, balancing energy production with the natural rhythms of light diffusion. It transforms farmers into solarfarmers, making them both cultivators and energy producers, independent and empowered to finance their transition to a greener future.

The thin plastic sheets covering greenhouses today last just 2-5 years, too often discarded, lost to the wind, drifting into nature and the Mediterranean Sea. With SolarHoop, disposable waste is replaced with something enduring and regenerative. Energy replaces pollution. Solar power replaces decay. Agriculture and technology move as one, shaping a future where sustainability is not an afterthought—it is the foundation.

PV Produce Drier

Agriculture, Desert

2018

Solar panels don’t just generate electricity—they also generate heat. The underside of a PV panel can reach temperatures 30°C hotter than the surrounding air, causing a 7.5% efficiency loss on scorching summer days. But what if that heat could be repurposed?

The PV Produce Drier transforms this excess energy into a low-cost, integrated drying system. By utilizing a specially designed array structure, it enhances air circulation, improving panel efficiency and longevity while simultaneously drying produce in a dedicated storage space.

The first prototype was installed on site. It consists of a 45 meter southern facing wall construction with a contained inner tunnel to allow for the passing of air.

Photovoltaic panels are installed on the wall structure at 45 degrees and ventilator is placed at one end of the tunnel. Sun produces more than enough energy (107.5kW to be exact) to power the ventilator which cools the solar modules.

The warm air is pushed to the opposite end of the tunnel, drying produce.

"This system tackles food waste and food security by transforming excess and imperfect produce into marketable dried goods, extending shelf life for wider distribution, reducing shipping costs through lighter weight, providing a viable solution for regions with limited infrastructure, and empowering farmers with the flexibility to delay fresh sales during low market prices, ultimately increasing profitability and independence."

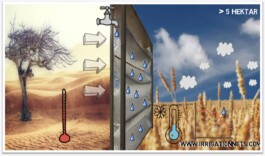

Irrigation Net

Agriculture

Spain

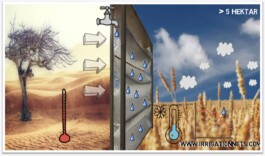

A decreasing water table and salinized groundwater pose serious challenges to this water- dependent region. As fresh water reserves are depleted, pressure from the sea replaces the empty space, permanently salinating the aquifer- that is until now. IrrigationNets provide a low-tech desalination solution, converting salty groundwater and seawater into fresh water. By ensuring a reliable water source, this innovation allows farmers to maintain cash crop production and silviculture, even in the face of droughts and climate instability.

The technology converts seawater or salinated groundwater into foggy, freshwater drizzle that directly supplies plants with a constant flow of cool moisture. The installation can be turned on and off as needed to meet the water requirements of various crops. The cooling effect leads to less water loss due to evaporation and reduced plant stress.

Over time the nets have the potential to restock groundwater levels and thereby prevent further seawater intrusion into coastal freshwater aquifers. They are a highly cost-efficient alternative to desalination plants and empower farmers to become independent from costly freshwater suppliers.

Collaboration with IrrigationNets has brought the technology to southern Spain. In our Agriculture lab the existing model was adapted to fit regional needs and made mobile. Tests are currently underway with the goal of reporting valuable information for local and other drought effected areas. This opportunity was all made possible by Volker Korrmann of IrrigationNets.

AgroMontemero

Agriculture

Spain

The AgroMontemero_02-21-V1 project piloted two innovative agroecological technologies aimed at reducing fossil fuel dependency in agriculture while enabling sustainable food production using saline water. The primary goal was to establish a self-sustaining microclimate across a 3.33-hectare area, requiring long-term monitoring for full assessment.

Key findings indicate that, despite challenges related to soil and water salinity, heat stress, and high radiation, environmental indexes reflect overall agroecosystem health. However, deficiencies in anthocyanin and chlorophyll production negatively impacted photosynthesis efficiency, resulting in a 25% plant loss and increased insect vulnerability under rising humidity and temperature conditions.

The IrrigationNets technology was tested from June to September, demonstrating localized cooling effects—air temperature reductions of up to 4.5°C at 15m, 4.0°C at 25m, and 1.5°C at 35m. Although it increased air humidity and lowered dew points, it was insufficient to mitigate plant moisture stress over the entire 3.33-ha area, as its effective influence was limited to a 40m radius.

To enhance agroecosystem resilience, a range of holohomeopathic treatments was applied from June 2021 to February 2022. These addressed photosynthesis efficiency, plant growth, phosphorus availability, pollinator attraction, solar filtration, heavy metal chelation, soil compaction resistance, drought tolerance, and fungal pathogen resistance. The project focused on crop and edible tree cultivation in 0.66 ha while managing microbial and insect trophic processes across 5 ha.

Overall, while the project demonstrated promising outcomes in microclimate regulation and plant resilience, further optimization of the technologies is needed to achieve broader-scale impact.

Agriculture

On the sunbaked coastal plains of Almería, a sea of greenhouses stretches beyond the horizon—40,000 hectares of translucent structures, the largest concentration on Earth. Beneath them, life flourishes. Nearly half of Europe’s produce is born here, nurtured by a system that has reshaped not only what we eat but also the climate, water cycles, and local ecology. To minimize this impact, Montemero works together with farmers to develop more efficient and sustainable farming technology- like evaporation control devices, recycled plastic and mycelium seed trays and other biodegradable supplies. These technologies are tested on site in the Agriculture Lab alongside an agroecology agriculture approach, continue to find out more about our innovations.

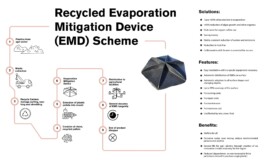

Evaporation Mitigation Device

Agriculture, Plastic, Desert

Spain

In southern Spain agriculture uses consume over 80% of available fresh water. Whats left is vulnerable to a 15% loss due to evaporation in the semi-arid region. The effects of climate change bring reality to water scarcity and the authority it plays over the region's prosperity for the future. Evaporation Mitigation Devices were designed to preserve this valuable resource, water. The floating, hexagonal pieces form a barrier against the sun and take the shape of any water reservoir.

01

In an effort to introduce circularity to the region while limiting environmental waste, we proposed an agriculture waste management scheme, enabling farmers to repurpose their spent agiplastic into new products- like EMDs. The resource saving devices are made 100% of reclaimed agripolymers.

02

A series of EMDs were formed and tested at our lab. We can report that they have shown an evaporation savings of 90% during the peak months of July, August and September. More notably, reducing algae growths by an average of 95% and therefore eliminate the need of toxic chemicals , often illegally dumped into reservoirs to prevent algae growth. These findings are the first of their kind and emphasise a REAL NEED for more research in this field for the region.

03

We have developed relations with a local agriplastic recycling facility, Green World Compounding, who is responsible for transforming large quantities of waste to a leach free composite.

04

The clean agripolymer composite can be used to produce the floating devices, a successful first for our partners Hexacover. With a lifespan of 20+ years, this technology can be applied and easily forgotten while its benefits are collected by the farmer and the environment for years to come.

"The EMDs represent more than technology—they embody a regenerative, circular future. Where waste becomes resource, and water is preserved for generations to come. A new way forward, where technology and nature work in harmony."

Germination Cells

Agriculture, Plastic, Fungi

Spain

These are the polystyrene trays that propagate young sprouts before planting. The trays are ubiquitous in agriculture and unfortunately, the environment, as strong winds and rain often carry them away. Polystyrene plastic is very difficult to recycle and once heavily soiled will likely reach its grave. We have developed several seed tray concepts to help resolve this concern.

In an effort to introduce circularity to the region, we proposed an agriculture waste management scheme, enabling farmers to recycle their spent agiplastic into new products- like seedtrays. The resource saving devices are made 100% of recycled agriplastic.

In a region where much immigrant exploitation takes place, the opportunity arose to provide young migrant workers a chance to surpass their current outlook in safe conditions with a liveable wage. With their help , 2 seed tray prototypes were developed from differing agriwaste- irrigation tubes and greenhouse coverings [white PP] and crates, twine and bulk bags [black LDPE].

To explore another area of circularity a 3rd seed tray prototype was developed using another common, but this time biodegradable, material- the tomato plant. The plant waste from tomato production was used as feedstock, mixed with mushroom mycelium and processed into an inactive form, establishing the first fully organic and compostable seed tray.

The recycled plastic and biodegradable seed trays solve several issues facing the region- give value to recycled plastic, provide examples of circularity, a solution to waste, prevent creation of excess waste, less environmental harm and many more.

PV Greenhouse

Agriculture, Desert

2018

Almeria enjoys over 300 days of sun a year making it the best place to harness the suns energy in photovoltaic solar panels. In fact the rays are so strong we’ve seen many hardy plants wither away beneath the endless days of sun, and this is where the opportunity arose. The solar panels are mounted to the roof of our greenhouse creating shade for distressed plants and purpose for the deadspace below the PVs.

The shade creates a pleasant microclimate that can be used for growing more seasonally exotic plants and produce. It also shields sprouts from aggressive pests.

Given that Almeria is known as the ‘plastic sea’ from outer space (the clusters of white greenhouses), it is clear that there is no short coming in having places to install the technology. With solar integration, these structures become more than food factories—they become energy farms, harnessing the sun twice over. By embracing rooftops as power stations, we protect the wild landscapes they would otherwise rest on

The next phase brings SolarHoop, an advanced PV film designed for greenhouses—flexible, lightweight, and seamlessly woven into the structure itself. Unlike rigid panels, SolarHoop breathes with the greenhouse, balancing energy production with the natural rhythms of light diffusion. It transforms farmers into solarfarmers, making them both cultivators and energy producers, independent and empowered to finance their transition to a greener future.

The thin plastic sheets covering greenhouses today last just 2-5 years, too often discarded, lost to the wind, drifting into nature and the Mediterranean Sea. With SolarHoop, disposable waste is replaced with something enduring and regenerative. Energy replaces pollution. Solar power replaces decay. Agriculture and technology move as one, shaping a future where sustainability is not an afterthought—it is the foundation.

PV Produce Drier

Agriculture, Desert

2018

Solar panels don’t just generate electricity—they also generate heat. The underside of a PV panel can reach temperatures 30°C hotter than the surrounding air, causing a 7.5% efficiency loss on scorching summer days. But what if that heat could be repurposed?

The PV Produce Drier transforms this excess energy into a low-cost, integrated drying system. By utilizing a specially designed array structure, it enhances air circulation, improving panel efficiency and longevity while simultaneously drying produce in a dedicated storage space.

The first prototype was installed on site. It consists of a 45 meter southern facing wall construction with a contained inner tunnel to allow for the passing of air.

Photovoltaic panels are installed on the wall structure at 45 degrees and ventilator is placed at one end of the tunnel. Sun produces more than enough energy (107.5kW to be exact) to power the ventilator which cools the solar modules.

The warm air is pushed to the opposite end of the tunnel, drying produce.

"This system tackles food waste and food security by transforming excess and imperfect produce into marketable dried goods, extending shelf life for wider distribution, reducing shipping costs through lighter weight, providing a viable solution for regions with limited infrastructure, and empowering farmers with the flexibility to delay fresh sales during low market prices, ultimately increasing profitability and independence."

Irrigation Net

Agriculture

Spain

A decreasing water table and salinized groundwater pose serious challenges to this water- dependent region. As fresh water reserves are depleted, pressure from the sea replaces the empty space, permanently salinating the aquifer- that is until now. IrrigationNets provide a low-tech desalination solution, converting salty groundwater and seawater into fresh water. By ensuring a reliable water source, this innovation allows farmers to maintain cash crop production and silviculture, even in the face of droughts and climate instability.

The technology converts seawater or salinated groundwater into foggy, freshwater drizzle that directly supplies plants with a constant flow of cool moisture. The installation can be turned on and off as needed to meet the water requirements of various crops. The cooling effect leads to less water loss due to evaporation and reduced plant stress.

Over time the nets have the potential to restock groundwater levels and thereby prevent further seawater intrusion into coastal freshwater aquifers. They are a highly cost-efficient alternative to desalination plants and empower farmers to become independent from costly freshwater suppliers.

Collaboration with IrrigationNets has brought the technology to southern Spain. In our Agriculture lab the existing model was adapted to fit regional needs and made mobile. Tests are currently underway with the goal of reporting valuable information for local and other drought effected areas. This opportunity was all made possible by Volker Korrmann of IrrigationNets.

AgroMontemero

Agriculture

Spain

The AgroMontemero_02-21-V1 project piloted two innovative agroecological technologies aimed at reducing fossil fuel dependency in agriculture while enabling sustainable food production using saline water. The primary goal was to establish a self-sustaining microclimate across a 3.33-hectare area, requiring long-term monitoring for full assessment.

Key findings indicate that, despite challenges related to soil and water salinity, heat stress, and high radiation, environmental indexes reflect overall agroecosystem health. However, deficiencies in anthocyanin and chlorophyll production negatively impacted photosynthesis efficiency, resulting in a 25% plant loss and increased insect vulnerability under rising humidity and temperature conditions.

The IrrigationNets technology was tested from June to September, demonstrating localized cooling effects—air temperature reductions of up to 4.5°C at 15m, 4.0°C at 25m, and 1.5°C at 35m. Although it increased air humidity and lowered dew points, it was insufficient to mitigate plant moisture stress over the entire 3.33-ha area, as its effective influence was limited to a 40m radius.

To enhance agroecosystem resilience, a range of holohomeopathic treatments was applied from June 2021 to February 2022. These addressed photosynthesis efficiency, plant growth, phosphorus availability, pollinator attraction, solar filtration, heavy metal chelation, soil compaction resistance, drought tolerance, and fungal pathogen resistance. The project focused on crop and edible tree cultivation in 0.66 ha while managing microbial and insect trophic processes across 5 ha.

Overall, while the project demonstrated promising outcomes in microclimate regulation and plant resilience, further optimization of the technologies is needed to achieve broader-scale impact.